LHMICV5100 Lub Tshuab Microscope Uas Siv Tau Tag Nrho

Txhua txoj haujlwm yog tsim raws li cov ntsiab cai ergonomic kom txo qhov kev qaug zog ntawm tus neeg teb xov tooj. Nws cov qauv tsim modular tso cai rau kev sib xyaw ua ke ntawm cov haujlwm ntawm lub kaw lus. Nws suav nrog ntau yam kev soj ntsuam, suav nrog lub teeb ci, lub teeb tsaus, lub teeb ci ntsa iab, lub teeb polarized, thiab DIC differential interferometry, nrog rau cov haujlwm xaiv tau raws li cov ntawv thov tshwj xeeb.

Txhawb nqa lub ntiaj teb ua tus thawj coj 25mm ultra-wide field of view, coj koj qhov kev paub tshiab dav dav. Ntau yam kev hloov kho diopter tuaj yeem ua tau raws li qhov xav tau ntawm ntau tus neeg siv. ntawm cov ntawv thov tshwj xeeb.

Cov hom phiaj semi-apochromatic uas ci ntsa iab thiab tsaus ntuj yog ua los ntawm cov iav uas xa tau zoo thiab cov thev naus laus zis siab heev los tsim cov xim ntuj ntawm cov qauv; tus qauv semi-apochromatic muaj kev kho xim zoo heev, txhim kho qhov sib piv thiab qhov meej ntawm daim duab uas pom.

Lub kaw lus polarization muaj xws li lub polarizer insert thiab lub analyzer insert, uas tuaj yeem ua qhov kev tshawb pom lub teeb polarized. Hauv kev tshuaj xyuas semiconductor thiab PCB, nws tuaj yeem tshem tawm lub teeb tsis pom kev thiab ua kom cov ntsiab lus meej dua.

Lub tshuab ntsuas kev sib hloov 360 ° tso cai rau kev saib xyuas yooj yim ntawm cov qauv tsos hauv qab lub teeb nrog cov kaum sab xis sib txawv yam tsis txav cov qauv.

● Lub theem XY uas muaj lub cev muaj zog siab, ua ke nrog lub kaw lus tswj hwm kaw, ua rau muaj kev luam theej duab loj thiab kev tsim cov duab ua tau zoo, kom ntseeg tau tias muaj kev sib koom ua ke ntawm ntau qhov chaw pom.

● Nws txhawb nqa txoj kev luam theej raws li koj xav tau, hloov kho rau cov qauv tsis sib xws, thiab txhim kho qhov kev vam meej ntawm kev sib txuas cov nto nyuaj.

●Lub Z-axis siv hluav taws xob, ua rau nws ua tau kom pom tseeb duab.

Lub lever nyob rau pem hauv ntej ntawm lub teeb ci ua rau kev hloov ntawm cov teb ci thiab cov teb tsaus yooj yim dua thiab muaj cov haujlwm txuas lim dej tsis sib xws. Qhov no tiv thaiv tus neeg siv lub qhov muag kom tsis txhob raug lub teeb ci ntsa iab thaum hloov ntawm cov teb tsaus mus rau cov teb ci, ua rau tus neeg siv xis nyob dua.

Ib lub cuab yeej hloov pauv ntau lub qhov (aperture) tso cai rau kev soj ntsuam zoo dua thiab txuas ntxiv mus ntawm qhov loj me qis, nruab nrab, thiab siab ntawm tib qho qauv ntawm ntau qhov chaw soj ntsuam sib txawv.

| Lub kaw lus kho qhov muag | Lub kaw lus kho qhov muag tsis kawg |

| Lub raj soj ntsuam | 30° qaij, infinity hinged peb txoj kev soj ntsuam raj, kev hloov kho qhov deb ntawm cov menyuam qhov muag: 50mm ~ 76mm, ob theem beam splitting ratio, binocular: trino = 100: 0 lossis 0: 100 |

| lub qhov muag | Qhov muag pom kev siab, qhov pom dav dav ntawm daim phiaj eyepiece PL10X / 25mm, diopter hloov kho tau. |

| Cov teb teeb thiab tsaus ntujLub lens semi-complex | LMPLFL 5X /0.15 BD DIC WD13.5mmLMPLFL10X/0.30 BD DIC WD9.0mmLMPLFL20X/0.5 BD DIC WD2.5mmLMPLFL50X/0.80 BD WD1.0mmLMPLFL100X / 0.90 BD WD 1.0mm |

| hloov pauv | 6-qhov converter rau lub teeb thiab tsaus teb, nrog rau DIC qhov |

| thav duab | Lub koob yees duab muaj lub thav duab reflector thiab lub tshuab coaxial coarse thiab fine focusing mechanism uas nyob qis qis. Qhov kev hloov kho coarse yog 25 hli, thiab qhov tseeb ntawm kev hloov kho fine yog 0.001 hli. Nws muaj lub cuab yeej tiv thaiv kev plam thiab lub qhov hloov siab tshaj plaws. |

| Lub teeb pom kev zoo | Lub teeb ci ntsa iab thiab lub teeb tsaus ntuj nrog lub diaphragm qhov hloov pauv tau, lub diaphragm teb, thiab qhov chaw hloov kho tau; nrog lub cuab yeej hloov teeb pom kev zoo thiab lub teeb tsaus ntuj; nrog qhov chaw lim xim thiab qhov chaw polarizer/analyzer. |

| chav teeb | Chav teeb halogen 12V 100W, tsim nyog rau ob qho kev sib kis thiab kev cuam tshuam, muaj rau kev txiav txim ua ntej. |

| Z-axis | Kev tsom xam tsis siv neeg |

| Lub platform hluav taws xob | Kev mus ncig ntawm lub platform: Kev taw qhia kab rov tav * Kev taw qhia ntsug = 80 * 60 (chav tsev: mm)Cov ntsia hlau ua: 2000μmXY repeatability raug: tsis pub dhau ± 2 μmZ-axis repeatability: tsis pub dhau ± 1 μmKev daws teeb meem ntawm 16 pawg: 0.625μm ib kauj ruam Lub kaum sab xis ntawm lub cev muaj zog stepper: 1.8 ° Tam sim no ua haujlwm: 1.0A ib lub ncej (powered by 24V) Qhov siab tshaj plaws thauj khoom: ≥5kg Qhov siab tshaj plaws ntawm kev mus los: 2 micrometers Qhov siab tshaj plaws ntawm cov qauv yog 25 hli (lwm qhov siab tuaj yeem hloov kho). |

| Lub thawv tswj kev tsav tsheb | Nws siv tus qauv RS232 serial chaw nres nkoj los sib txuas lus nrog lub PC (115200 baud rate).Kev tswj hwm chaw nres nkoj serial tso cai rau kev teeb tsa lub cev muaj zog qhov ceev, qhov deb, thiab kev taw qhia ntawm kev txav mus los. |

| Lwm cov ntaub ntawv txuas | Cov ntxig polarizer, cov ntxig analyzer tig tau 360°, thiab cov lim dej cuam tshuam teeb tsa rau kev cuam tshuam. |

| Kev Tshawb Fawb Txog Kev Tshawb Fawb | FMIA 2025 cov software tshuaj xyuas metallographic tiag tiag thiab cov software porosity |

| lub koob yees duab | 5 megapixels, 36 fps |

| 0.5X adapter lens interface, micrometer | |

| Cov khoos phis tawj tswj kev lag luam | Intel i5 processor, 64GB RAM, 1TB SSD, 27-nti 4K saib |

Peb cov software tshuaj xyuas duab metallographic yog ib lub tshuab tshiab tsim los ntawm peb lub tuam txhab raws li kev xav tau kev kuaj metallographic ntawm cov tuam txhab casting, cov tuam txhab khoom siv tsheb, cov tuam txhab kho cua sov, kev lag luam hlau bearing, kev lag luam fais fab, kev lag luam khoom siv tsheb ciav hlau, thiab ntau lub tuam txhab kuaj xyuas cuam tshuam. Txhawm rau txhim kho tus nqi tsim nyog ntawm cov khoom thiab pab txhim kho qib kev xeem ntawm ntau lub chaw soj nstuam, peb tau sau cov kev xav tau thiab kev xav ntawm cov kws tshaj lij thiab cov xib fwb los ntawm ntau yam kev lag luam.

Cov software tshuaj xyuas duab metallographic tau dhau los ua qhov tsim dua tshiab thiab hloov kho dua tshiab. Lub kaw lus npog ntau tus qauv kev xeem metallographic hauv tebchaws thiab thoob ntiaj teb, sib xyaw ua ke kev tshuaj xyuas kom muaj nuj nqis thiab zoo, thiab ntxiv qhov tob ntawm daim teb synthesis thiab cov haujlwm ntawm daim duab teb-ntawm-saib stitching. Lub interface yooj yim thiab tuaj yeem ntes cov duab ntau daim teb-ntawm-saib rau kev teeb tsa duab hauv nruab nrab thiab kev tshuaj xyuas. Kev ua haujlwm yooj yim dua, tshem tawm ntau yam kauj ruam cumbersome ntawm cov software dhau los, ua rau kev sim sai dua thiab ua haujlwm tau zoo dua.

Peb tau tsim ib lub cuab yeej tshuaj xyuas metallographic tshiab "kev tshaj lij, raug, thiab ua haujlwm tau zoo" los ua kom yooj yim rau kev tshuaj xyuas metallographic.

Lub tsev qiv ntawv txheem hauv tebchaws ntawm lub kaw lus software muaj ntau pua pawg, feem ntau yog hais txog cov qauv metallographic uas siv ntau thiab ua tau raws li cov kev xav tau ntawm kev tshuaj xyuas metallographic thiab kev sim ntawm feem ntau ntawm cov koom haum. Cov pawg cuam tshuam tau teev tseg thiab qhib raws li qhov xav tau ntawm ntau yam kev lag luam kom ua tau raws li cov kev xav tau ntawm kev sim kev lag luam. Txhua lub modules muaj pub dawb rau lub neej, thiab cov qauv raug hloov kho pub dawb rau lub neej.

Vim muaj cov ntaub ntawv tshiab thiab cov qib xa tuaj ntau zuj zus, cov ntaub ntawv thiab cov qauv ntsuas uas tseem tsis tau suav nrog hauv software tuaj yeem hloov kho thiab nkag mus rau nyias.

Cov txiaj ntsig thiab kev ua haujlwmCov software tshuaj xyuas metallographic:

- Kev ntes thiab txais cov duab video ua ke: Kev tua ib pawg, kev muab lub npe rau ib pawg, kev txuag ib pawg, kev luam ntawv ib pawg nrog kev loj hlob ruaj khov thiab lwm yam kev ua haujlwm ntawm ntau daim duab ua rau cov txheej txheem tshuaj xyuas cov qauv ib pawg yooj yim dua thiab ua haujlwm tau zoo dua.

- Qib Siabchaw teeb tsa lub koob yees duab:Lub sijhawm raug, qhov nce, qhov ntse, qhov saturation, gamma, qhov sib piv, qhov ci, qhov sib npaug dawb, qhov sib npaug dub, thiab lwm yam kev teeb tsa ua haujlwm.

- Nyem ib zaug xwbkev kho kom raug rau txhua lub hom phiaj:Lub luag haujlwm calibration tau hloov kho dua tshiab tag nrho, cia koj ua tiav qhov calibration ntawm txhua qhov kev ntsuas nrog ib qho nias. Piv rau txoj kev calibration qub, txoj kev calibration tshiab yooj yim dua thiab ua haujlwm sai dua.

- Cov haujlwm ua duab:Kev sib cais xim, kev hloov pauv greyscale, kev teeb tsa qhov tseem ceeb, kev sib xyaw ua ke, kev txhim kho duab, kev hloov pauv theem, kev ua kom ntse, kev tshem tawm khawb thiab smudge, duab histogram, thiab lwm yam.

- Cov zis ntawm cov duab scaling:Cov yam ntxwv suav nrog kev luam ntawv ntau daim duab, cov npe duab kev cai, qhov chaw teeb tsa ntsuas, xa tawm mus rau PDF / Word / Excel, thiab saib ua ntej luam tawm.

Kev ntsuas thiab khaws cov duab:Muaj ntau yam cuab yeej ntsuas (xws li qhov deb, lub kaum sab xis, lub kaum sab xis ntawm ob kab, lub duab plaub fab, qhov deb ntawm qhov taw tes rau kab, ellipse, polygon, qhov deb ntawm kab sib luag, peb-taw tes arc, peb-taw tes voj voog, thiab lwm yam), uas tso cai rau kos xub, sau cov ntawv, thiab ntxiv ... Muaj ntau txoj kev xaiv rau cov kab pabcuam, qhov dav ntawm kab, thiab qhov ntev; cov ntaub ntawv ntsuas xim ntawv, qhov loj me, thiab hom ntawv kuj muaj; cov ntaub ntawv xeem tuaj yeem raug sau ua ke thiab xa tawm mus rau Excel.

Kev ua haujlwm ntawm kev tshuaj xyuas lub koom haum:Lub tsev qiv ntawv software muaj ntau yam qauv xeem sib txawv, suav nrog GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS thiab lwm yam qauv kev tshuaj xyuas lub koom haum. Cov qauv hauv lub tsev qiv ntawv software tuaj yeem hloov kho dawb, thiab software muaj peev xwm tshuaj xyuas tsis siv neeg thiab sib piv. Nws muaj peb lub luag haujlwm metallographic grading: thawj, thib ob, thiab kev pabcuam. Nws yooj yim, yooj yim, thiab ceev ceev siv, thiab muab cov kev ntsuas tseeb thiab txhim khu kev qha.

Cov yam ntxwv kho kom haum siab heev:Kev tswj theem uas siv lub tshuab microscope uas hloov kho raws li qhov xav tau, kev sib sau ua ke ntawm cov duab, kev kos duab 3D, cov ntaub ntawv duab, thiab lwm yam.

Cov qauv qhia sib txawv:Tsim cov ntawv qhia txog kev tshuaj xyuas metallographic uas muaj cov duab kos zoo nkauj, nrog rau kev xaiv rau cov qauv ntawv qhia ib-module lossis ntau-module. Cov qauv ntawv qhia tuaj yeem hloov kho kom suav nrog cov logos ntawm lub tuam txhab, cov npe ntawm lub tuam txhab, cov txheej txheem kuaj, thiab lwm yam ntaub ntawv. Cov qauv ntawv qhia tshwj xeeb kuj muaj los ua kom tau raws li koj cov kev xav tau tshwj xeeb.

Kev ua haujlwm ntawm AI-powered tissue analysis:Ib qho module tsom xam cov ntaub so ntswg AI uas hloov kho tau siv kev txawj ntse los ua kom tiav tag nrho cov txheej txheem tsom xam thiab nrhiav pom microstructure, txiav txim siab thiab tshuaj xyuas cov microstructure ntawm cov ntaub ntawv. Cov txheej txheem ua haujlwm yooj yim, txo qhov kev siv zog ntawm cov neeg ua haujlwm. Txhim kho qhov ua tau zoo ntawm kev sim cov ntaub ntawv.

Lub Tsev Qiv Ntawv Kos Duab Txuj Ci Hauv Tebchaws:Muaj ntau pua daim duab kos qauv hauv tebchaws rau cov neeg siv khoom kawm thiab siv.

Cov Qauv Qhia Txog Metallography:Muaj xws li ib qho module qhia metallography rau cov neeg siv khoom kawm thiab xa mus rau.

EDF Qhov tob ntawm kev nthuav dav teb:Rau cov qauv uas tsis sib npaug thiab tsis tuaj yeem sib phim hauv qhov tsom xam, cov software muab qhov kev ua haujlwm tua duab EDF dynamic. Los ntawm kev kho lub microscope's Z-axis micro-adjustment focusing handwheel, cov ntsiab lus meej hauv cov qauv yuav raug ntxiv tas li rau lub qhov rais dynamic EDF rau kev hloov kho tshiab. Cov software cia li kaw cov duab meej ntawm qhov tob sib txawv thiab sib koom ua ke rau hauv cov duab meej.

Kev ua haujlwm ntawm cov duab stitching:Rau cov neeg siv khoom uas xav tau kev tshuaj xyuas qhov pom dav dua, cov software muab kev ua haujlwm sib txuas duab. Cov neeg siv tuaj yeem txav lub tshuab microscope lub XY platform kom ua tiav kev luam theej duab puv ntoob thiab kev sib xyaw ua ke ntawm cov duab ua tau zoo kom ntseeg tau tias muaj kev sib txuas ntawm ntau qhov pom. Qhov no ua tau raws li qhov xav tau ntawm cov neeg siv khoom los ntes cov duab ntawm cov qauv loj dua thiab daws qhov txaj muag ntawm kev tsis tuaj yeem thaij duab vim tsis muaj qhov pom dav dav ntawm lub tshuab microscope txaus.

Nws txhawb nqa cov kev ntsuas kev cai, hloov kho rau cov qauv tsis sib xws, thiab txhim kho qhov kev vam meej ntawm kev sib txuas cov nto nyuaj.

Lub Z-axis siv hluav taws xob, ua rau nws ua tau kom pom tseeb duab.

| GB/T 10561-2023 Kev Txiav Txim Siab Txog Cov Ntsiab Lus Uas Tsis Yog Hlau Hauv Hlau | GB/T 34474.1-2017 Kev ntsuam xyuas ntawm cov qauv banded hauv hlau |

| GB/T 7216-2023 Kev Tshuaj Xyuas Metallographic ntawm Grey Cast Iron | DL/T 773-2016 Tus Qauv Ntsuas Spheroidization rau 12Cr1MoV Hlau Siv Hauv Cov Chaw Tsim Hluav Taws Xob Thermal |

| GB / T 26656 - 2023 Kev Tshuaj Xyuas Metallographic ntawm Vermicular Graphite Cast Iron | DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Kev Ntsuas Kev Laus |

| GB/T 13299-2022 Txoj Kev Ntsuam Xyuas rau Microstructure ntawm Hlau | GB / T 3489-2015 Cov hlau nplaum tawv - Kev txiav txim siab metallographic ntawm porosity thiab cov pa roj carbon tsis sib xyaw ua ke |

| GB/T 9441-2021 Kev Tshuaj Xyuas Metallographic ntawm Cov Hlau Ductile | JB/T 1255-2014 Cov Kev Cai rau Kev Kho Mob Kub ntawm Cov Hlau Carbon Chromium Bearing Steel Parts rau Rolling Bearings |

| GB/T 38720-2020 Kev Tshuaj Xyuas Metallographic ntawm Cov Hlau Carbon Nruab Nrab Quenched thiab Cov Hlau Carbon Alloy Nruab Nrab | GB / T 1299 - 2014 Cov Cuab Yeej thiab Cov Hlau Tuag |

| GB/T 224-2019 Txoj Kev Txiav Txim Siab Txog Qhov Tob Ntawm Cov Txheej Decarburized Hauv Cov Hlau | GB / T 25744 - 2010 Kev Tshuaj Xyuas Metallographic ntawm Carburized, Quenched, thiab Tempered Steel Parts |

| TB/T 2942.2-2018 ZG230-450 Kev Tshuaj Xyuas Metallographic ntawm Cov Hlau Cam Khwb Cia | GB/T13305-2008 Kev txiav txim siab ntawm cov ntsiab lus ntawm thaj chaw α-theem hauv cov hlau tsis xeb |

| JB/T 5108-2018 Kev Tshawb Fawb Txog Metallographic ntawm Cast Brass | JB/T 9204-2008 Kev Tshuaj Xyuas Metallographic ntawm Induction Hardened Steel Parts |

| GB / T 6394-2017 Txoj Kev Txiav Txim Siab Qhov Nruab Nrab Qhov Loj ntawm Cov Hlau | GB/T 13320-2007 Cov hlau forgings, cov duab qhia txog cov qauv metallographic thiab cov txheej txheem ntsuam xyuas |

| JB/T7946.1-2017 Metallography ntawm Cast Aluminium Alloys | DL/T 999-2006 Tus Qauv Ntsuas Hlau Spheroidized rau Cov Chaw Tsim Hluav Taws Xob |

| JB/T7946.2-2017 Kev Kub Dhau ntawm Cov Khoom Siv Aluminium-Silicon | DL/T 439-2006 Cov Lus Qhia Txog Kev Siv Rau Cov Khoom Siv Kub Siab Hauv Cov Chaw Tsim Hluav Taws Xob Thermal |

| JB/T7946.3-2017 Cam khwb cia txhuas hlau Pinhole | DL/T 786-2001 Tus Txheej Txheem rau Kev Ntsuas thiab Kev Ntsuas ntawm Graphitization ntawm Carbon Steel |

| JB/T 7946.4-2017 Metallography ntawm Cast Aluminium Alloys | B/T 1979-2001 Daim duab qhia txog qhov tsis zoo ntawm cov qauv hlau uas muaj qhov loj me me |

| GB / T 34891 - 2017 Rolling Bearings_Technical Cov Kev Cai rau Kev Kho Mob Kub ntawm Cov Khoom Siv Hlau Carbon Chromium Siab | DL/T 674-1999 Tus Qauv rau Pearlite Spheroidization Rating ntawm No. 20 Steel rau Thermal Power Plants |

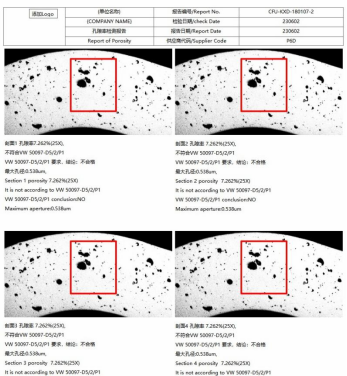

Lub tshuab ntsuas duab porosity FKX2025 siv cov duab microscopic los ntes qhov porosity ntawm cov khoom siv hauv tsheb. Nws yog lub tshuab ntsuas porosity rau cov txhuas cam khwb cia siv hauv kev lag luam tsheb, ua raws li Volkswagen tus qauv VW50097 thiab PV6097. Cov txiaj ntsig ntsuas tau raug thiab txhim khu kev qha. Nws feem ntau yog siv rau kev tshuaj xyuas qhov casting porosity ntawm cov hlau txhuas thiab cov hlau cam khwb cia, thiab kuj tsim nyog rau kev tshuaj xyuas porosity thiab kev tshuaj xyuas metallographic ntawm lwm cov ntaub ntawv.

Cov software tshuaj xyuas duab porosity siv tau nrog theem hluav taws xob kom ua tiav kev luam theej duab tsis siv neeg, kev tsom mus rau tsis siv neeg, kev sib dhos duab tsis siv neeg, kev ntsuas porosity tsis siv neeg, cov ntaub ntawv txheeb cais, thiab cov ntawv tshaj tawm.

Kev ua haujlwm ntawm cov duab stitching:Teem cov kev teeb tsa thiab hom duab, nyem "Auto Stitch," thiab kev teeb duab yuav ua tiav tau.

Kev teeb tsa parameter nrhiav:Los ntawm kev teeb tsa thaj chaw tsawg kawg nkaus, thaj chaw siab tshaj plaws, thiab qhov txwv, kev tshawb nrhiav daim ntawv qhia tag nrho tuaj yeem ua tiav los nrhiav txhua qhov pores hauv cov kev teeb tsa ntawm tag nrho daim ntawv qhia.

Kev xaiv duab:Muab cov cuab yeej xaiv xws li lub duab plaub fab, lub duab ntau sab, lub voj voog, lub duab plaub fab, thiab lub duab peb ceg. Tom qab xaiv tiav lawm, cov software yuav ua qhov kev tshuaj xyuas porosity ntawm thaj chaw xaiv.

Kev tshuaj xyuas qhov hws:Nws tuaj yeem tshuaj xyuas cov ntaub ntawv xws li qhov puag ncig, thaj chaw, qhov loj axis, qhov me axis, qhov sib npaug ntawm lub voj voog, qhov sib piv ntawm qhov pom, thiab qhov puag ncig ntawm txhua lub qhov.

Kev ntsuas geometric:Muaj ntau yam cuab yeej ntsuas siv tau rau kev ntsuas qhov ntev

Cov ntaub ntawv txheeb cais thiab kev tsim cov ntawv qhia:Nws tuaj yeem tshuaj xyuas cov ntaub ntawv qhia txog cov ntsiab lus rau txhua lub qhov thiab tsim ob hom kev tshaj tawm, VW50093 lossis VW50097.