1) Puas siv tau lub Rockwell hardness tester los ntsuas qhov nyuaj ntawm phab ntsa yeeb nkab hlau?

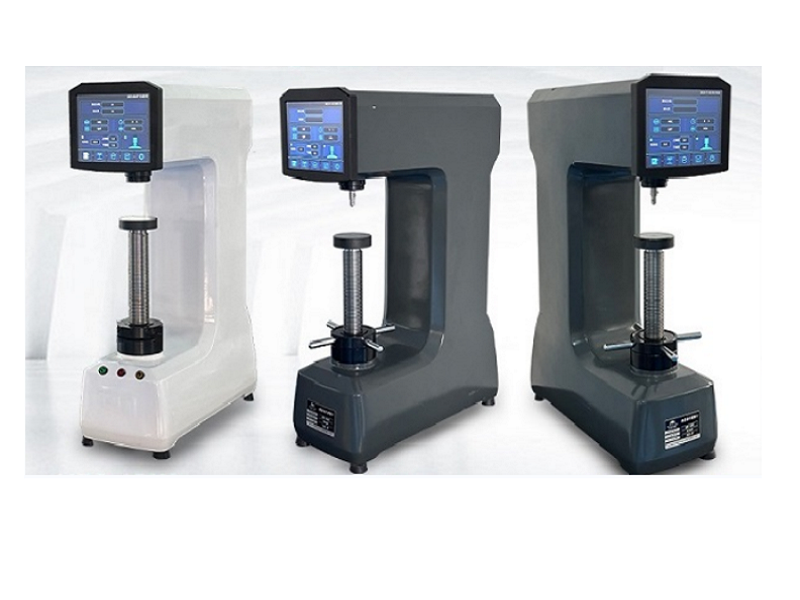

Cov khoom siv kuaj yog SA-213M T22 steel yeeb nkab nrog lub cheeb sab nraud ntawm 16 hli thiab phab ntsa tuab ntawm 1.65 hli. Cov txiaj ntsig ntawm kev kuaj Rockwell hardness yog raws li nram no: Tom qab tshem tawm cov nplai oxide thiab txheej decarburization ntawm qhov chaw ntawm cov qauv nrog lub grinder, cov qauv raug muab tso rau ntawm lub rooj ua haujlwm V-puab, thiab HRS-150S digital Rockwell hardness tester siv los kuaj ncaj qha Rockwell hardness ntawm nws qhov chaw sab nraud nrog lub nra ntawm 980.7N. Tom qab kev kuaj, nws tuaj yeem pom tias phab ntsa yeeb nkab hlau muaj qhov deformation me ntsis, thiab qhov tshwm sim yog tias Rockwell hardness tus nqi ntsuas qis dhau, ua rau kev kuaj tsis raug.

Raws li GB/T 230.1-2018 «Metallic Materials Rockwell Hardness Test Part 1: Test Method», Rockwell hardness yog 80HRBW thiab qhov tsawg kawg nkaus ntawm cov qauv tuab yog 1.5 hli. Qhov tuab ntawm cov qauv No. 1 yog 1.65 hli, qhov tuab ntawm cov txheej decarburized yog 0.15 ~ 0.20 hli, thiab qhov tuab ntawm cov qauv tom qab tshem cov txheej decarburized yog 1.4 ~ 1.45 hli, uas ze rau qhov tsawg kawg nkaus ntawm cov qauv teev tseg hauv GB/T 230.1-2018. Thaum lub sijhawm sim, vim tias tsis muaj kev txhawb nqa hauv nruab nrab ntawm cov qauv, nws yuav ua rau me ntsis deformation (uas tej zaum yuav tsis pom los ntawm lub qhov muag liab qab), yog li qhov tseeb Rockwell hardness tus nqi qis.

2) Yuav ua li cas xaiv lub tshuab ntsuas qhov nyuaj ntawm cov kav hlau:

Tom qab ntau qhov kev sim ntawm qhov nyuaj ntawm cov kav hlau, peb lub tuam txhab tau los txog rau cov lus xaus hauv qab no:

1. Thaum ua qhov kev sim Rockwell hardness lossis Rockwell hardness ntawm qhov chaw ntawm cov kav hlau nyias nyias, kev txhawb nqa phab ntsa yeeb nkab tsis txaus yuav ua rau cov qauv deformation thiab ua rau cov txiaj ntsig xeem qis;

2. Yog tias muaj kev txhawb nqa cylindrical ntxiv rau hauv nruab nrab ntawm cov yeeb nkab hlau nyias-phab ntsa, cov txiaj ntsig ntawm kev sim yuav qis vim tias lub axis ntawm lub taub hau siab thiab kev taw qhia ntawm kev thauj khoom tsis tuaj yeem ua kom ntseeg tau tias yuav tsum perpendicular rau qhov chaw ntawm cov yeeb nkab hlau, thiab muaj qhov sib txawv ntawm qhov chaw sab nraud ntawm cov yeeb nkab hlau thiab kev txhawb nqa cylindrical uas tau teeb tsa.

3. Txoj kev hloov qhov ntsuas Vickers hardness mus rau Rockwell hardness tom qab inlaying thiab polishing cov yeeb nkab steel qauv yog qhov tseeb.

4. Tom qab tshem tawm cov oxide scale thiab decarburization txheej ntawm qhov chaw ntawm cov yeeb nkab hlau thiab machining lub dav hlau xeem ntawm qhov chaw sab nraud thiab inlaying nws, qhov chaw Rockwell hardness hloov pauv mus rau Rockwell hardness, uas yog qhov tseeb.

Lub sijhawm tshaj tawm: Lub Rau Hli-13-2024