Muaj ntau hom txheej hlau. Cov txheej sib txawv xav tau cov zog sib txawv hauv kev sim microhardness, thiab cov zog sim tsis tuaj yeem siv random. Hloov chaw, kev sim yuav tsum tau ua raws li cov nqi zog sim pom zoo los ntawm cov qauv. Niaj hnub no, peb yuav qhia txog kev sim micro Vickers hardness ntawm zinc coatings lossis zinc-aluminium-magnesium alloy coatings siv rau ntawm hlau.

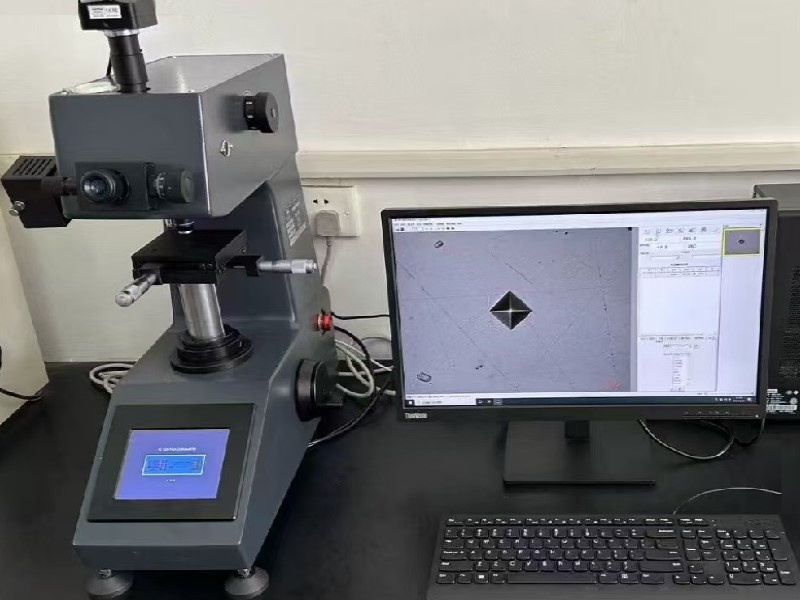

1. Kev npaj cov qauv metallographic zoo ntawm cov txheej zinc (lossis cov txheej txhuas-magnesium) yog thawj kauj ruam hauv kev sim txheej. Kev npaj cov qauv txheej zinc muaj ntau kauj ruam, suav nrog kev kuaj, kev teeb tsa, thiab kev sib tsoo ua ntej thiab kev txhuam. Lub hom phiaj ntawm kev npaj cov qauv no yog los sib tsoo qhov chaw hla ntawm qhov workpiece mus rau hauv qhov chaw du, tiaj tus uas tso cai rau kev pom tseeb ntawm Vickers indentations, pab txhawb kev ntsuas qhov tseeb ntawm qhov indentation kom tau txais cov nqi hardness.

2. Rau kev kuaj qhov nyuaj ntawm cov txheej zinc: vim tias cov txheej zinc tuab heev, kev kuaj qhov nyuaj tuaj yeem ua tiav nrog cov zog sib txawv. Ntawm tib tus qauv, qhov me dua ntawm lub zog sim siv, qhov me dua qhov loj ntawm qhov nkag; ntawm qhov tod tes, qhov loj dua ntawm lub zog sim, qhov loj dua qhov nkag. Yog tias cov txheej txheej nyob ib puag ncig qhov nkag qhia cov cim ntawm kev tawg lossis deformation, lub zog sim me dua yuav tsum tau xaiv. Cov txheej txheem no rov ua dua kom txog thaum cov txheej txheej nyob ib puag ncig Vickers indentation tseem zoo li qub yam tsis muaj kev hloov pauv - qib zog sim no yog qhov tsim nyog rau cov qauv.

2.1 Cov txheej tuab sib txawv sib raug rau cov zog kuaj tshwj xeeb, uas yog qhov tseem ceeb rau kev zam kev cuam tshuam ntawm cov txiaj ntsig xeem. Cov hauv qab no yog cov ntaub ntawv siv rau kev xaiv lub zog kuaj rau cov txheej txheem sib xws (zinc plating, chromium plating), siv tau rau micro Vickers hardness testers (HV):

| Hom txheej | Txheej Qhov tuab (μm) | Pom zoo Lub Zog Ntsuas (gf) | Sib raug zoo HV Nplai | Cov Kev Ceeb Toom Tseem Ceeb |

| Zinc Kev plating | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Zinc plating yog qhov mos mos (feem ntau HV50 ~ 150); lub zog me me tiv thaiv kev nkag mus ntau dhau. |

| Zinc Kev plating | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Thaum cov tuab zuj zus, lub zog tuaj yeem raug tsa kom zoo kom ntseeg tau tias cov npoo ntawm cov ntawv nkag mus meej. |

| Chromium Kev plating | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Cov chromium tawv (HV800 ~ 1200) muaj qhov nyuaj siab; lub zog me me tiv thaiv kev puas tsuaj rau lub indenter. |

| Chromium Kev plating | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Thaum tuab > 10μm, HV0.1force sib npaug qhov tseeb thiab kev ua haujlwm zoo. |

| Sib xyaw ua ke Txheej | <5 | ≤25 | HV0.01, HV0.025 | Rau cov txheej txheej xws li zinc-nickel alloy thiab chromium-nickel alloy, nruj me ntsis tiv thaiv kom tsis txhob muaj qhov nkag mus rau hauv txheej txheej. |

2.2 Lwm Yam Tseem Ceeb Uas Cuam Tshuam

Ntxiv rau qhov tuab, ob yam hauv qab no yuav hloov pauv qhov kev xaiv ntawm lub zog sim, thiab yuav tsum txiav txim siab raws li qhov xwm txheej tiag tiag:

Txheej Hardness Ntau Yam:

Cov txheej txheej mos (piv txwv li, zinc plating, HV < 200): Yog tias lub zog sim me dhau, qhov indentations yuav tsis meej vim yog cov yas deformation ntawm cov txheej txheej. Nws raug pom zoo kom xaiv qhov txwv siab tshaj plaws ntawm qhov ntau yam pom zoo (xws li., tuab 10 μm, xaiv 50gf lub zog sim).

Cov txheej tawv tawv (piv txwv li, chromium plating, HV > 800): Qhov tawv tawv ua rau muaj qhov me me, yog li lub zog sim yuav tsum tsis txhob me dhau (xws li, tuab 5 μm, xaiv 25gf lub zog sim) kom tiv thaiv qhov yuam kev ntsuas ntawm kab pheeb ces kaum ntawm qhov tsis pub dhau ± 5%.

2.3 Cov Kev Cai ntawm Cov Qauv thiab Cov Lus Qhia Tshwj Xeeb

Cov lag luam sib txawv muaj cov qauv meej. Piv txwv li:

Kev lag luam tsheb feem ntau siv ISO 14577 (Instrumented Indentation Test), uas tso cai rau kev kho qhov muaj zog raws li qhov tuab ntawm txheej;

Kev lag luam dav dav yog hais txog ASTM E384, uas yuav tsum tau kom lub kab pheeb ces kaum ntawm qhov indentation yog ≤ 1/2 ntawm qhov tuab ntawm txheej thiab ≥ 10 npaug ntawm lub vojvoog ntawm lub taub hau indenter (kom tsis txhob muaj qhov cuam tshuam ntawm lub taub hau).

Xaus lus, kev xaiv lub zog sim rau kev sim micro-Vickers hardness ntawm cov xim hlau yuav tsum ua raws li cov laj thawj ntawm "tuab ua ntej, kev kho qhov nyuaj, thiab kev lees paub tus qauv":

Ua ntej, txiav txim siab qhov ntau ntawm lub zog sim raws li qhov tuab ntawm txheej (saib cov lus saum toj no);

Kho qhov nqi zog raws li qhov nyuaj ntawm cov txheej (xaiv qhov txwv sab saud rau cov txheej mos thiab qhov txwv qis rau cov txheej tawv);

Thaum kawg, ua raws li cov qauv kev lag luam (xws li ISO 14577 thiab ASTM E384) kom ntseeg tau tias qhov tseeb ntawm cov txiaj ntsig xeem.

Lub sijhawm tshaj tawm: Cuaj hlis-03-2025